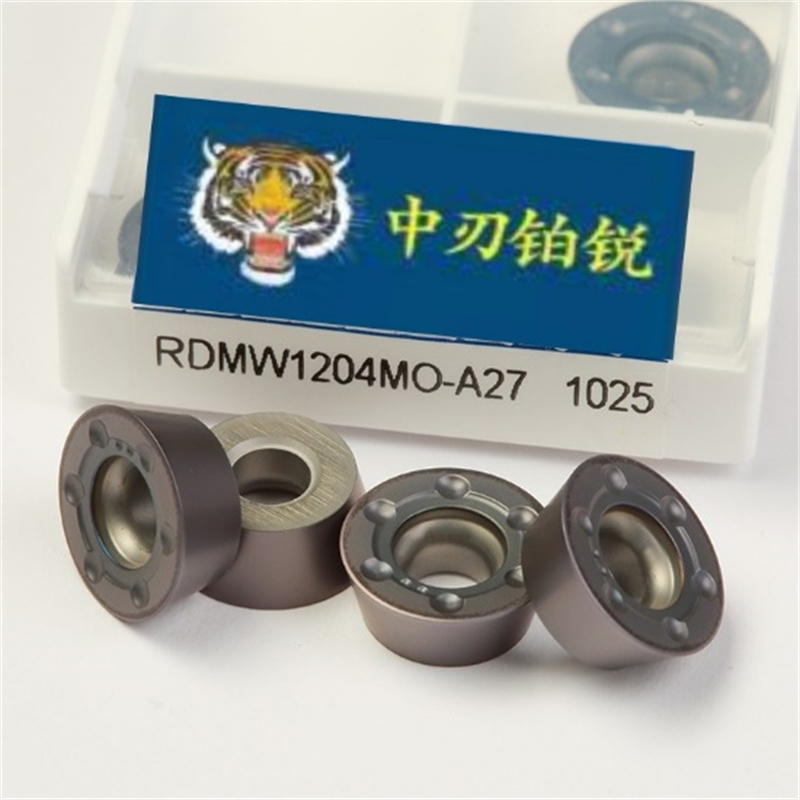

ʻO CNC Indexable Turning Tools Lathe Carbide WNMU080608 High Feed Face Milling Inserts WNMU 080608

ʻIke Kumu

Nā huahana nui:

Milling :APMT APKT RDMT RPMT LNMU BLMP SEKT SDMT SOMT SEKN SEEN SPKN TPKN TPKR TPMR 3PKT WNMU SNMU ONMU AOMT JDMT R390 BDMT

Huli:CNMG CCMT SNMG SCMT WNMG TNMG TCMT DCMT DNMG VNMG VBMT KNUX

KaMGMN MRMN N151 N123 ZTFD TDC2 TDC3 TDC4

No ka alumini:APGT APKT CCGT DCGT VCGT RCGT SCGT SEHT TCGT ZTED

Heluhelu:11IR 11ER 16ER 16IR 22ER 22IR

U Drill:SPMT WCMX WCMT

Ka hao:CNMA DNMA SNMA TNMA VNMA WNMA

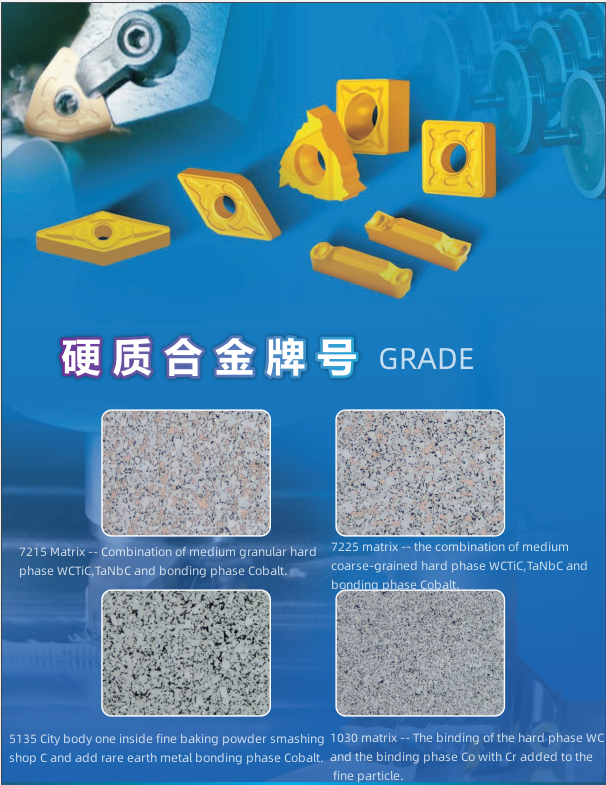

Hoʻolauna Papa Mea

Introduction o ka hoʻohuli mea hoʻolauna:

ʻO 7215 ka ikaika kiʻekiʻe a me ka paʻakikī o ka matrix kū'ē i nā meaʻawaʻawa, i hui pūʻia

me MT-TICN, AL2O3, TIN hui maikaʻi o ke kaʻina hana uhi, a laila

ma o ka uhi ʻana ma hope o ka lapaʻau ʻana e hoʻopau i ke koʻikoʻi o loko o ka papa lau, kūpono no ka hoʻopau kila maʻamau.

7125 lihi palekana o ka ikaika kiʻekiʻe, kiʻekiʻe toughness matrix hui pū me MT-TICN a me ka superfriction AL203 kaʻina hana, a laila ma o ke kaʻina hana hoʻoponopono hope e hoʻopau ai i ke koʻikoʻi o loko o ka uhi, kūpono no ka hana kila kila maʻamau, semi-finishing a hapa o ka workpiece roughness koi 'aʻole kiʻekiʻe hoʻopau.

4025 kiʻekiʻe corrosion kū'ē, a ma o kekahi puʻe sintering kaʻina o kiʻekiʻe ikaika matrix a me MT-TICN a super mānoanoa AL2O3 uhi hui maikaʻi loa, me ka kiʻekiʻe ka uhi 'ana ma hope o ka 'ike loea no ka loaʻaʻana o ka maʻemaʻe machining machining, semi-hoʻopau. a me ka hoopau ana i ka hao.

1030 palaoa maikaʻi, maikaʻi deformation kū'ē a ma o ke kaomi sintering kaʻina e loaʻa ultra-kiʻekiʻe kiʻekiʻe a me ke kuʻekuʻe matrix, me nano PVD kaʻina hana, a laila ma o ka holomua hoʻopili hope-lāʻau e loaʻa maʻemaʻe ili uhi, kūpono no ka maʻamau kila hoʻopau. ke kila kinai ʻia, ke kila chromium a me ke kila kila semi-finishing a me ka hoʻopau ʻana.

1120 ultra-fine palaoa, maikaʻi deformation kū'ē, a ma o ke kaomi sintering kaʻina e loaʻa kiʻekiʻe kiʻekiʻe aʻaʻahu kū'ē matrix, me nano SI loaʻa PVD kaʻina kaʻina hana, ma hope o kiʻekiʻe ka uhi ana ma hope o ka hoʻomaʻamaʻa e kiʻi maʻemaʻe ili uhi.He kūpono no ka ʻokiʻoki ʻana i ke kila maʻamau, ke kila paʻakikī a me ka hao hoʻolei.

Hoʻokomo i nā mea wili a me nā mea wili

ʻO 1030 NC-TIALN ka uhi i hui pū ʻia me ka matrix ikaika a me ka ductile o nā ʻāpana maikaʻi e kūpono no ka wili ʻana a me ka semi-finished o nā ʻano mea i hana ʻia.ʻO ka grooving, ka ʻoki ʻana a me ka ʻeli ʻana o ka hapalua puka.

ʻO ka 1130 NC-TIALN uhi i loaʻa iā SI ua hui pū ʻia me nā ʻāpana maikaʻi a me ka paʻakikī maikaʻi o ka matrix alloy paʻakikī, kūpono no ke kila kila, ka hao hao a me ka semi-finish i ka hana ʻana, e hoʻokō i kahi hui kūpono o ka palekana a me ke kūpaʻa ʻana.

5035 hoʻohui i ka lole a me ke kiʻekiʻe wela o ka pale ʻana o ka CVD coating, ka paʻakikī paʻa kiʻekiʻe a me ke kūpaʻa kiʻekiʻe kiʻekiʻe e hāʻawi i ka pale kūpono no ka ʻoki ʻana, ka ʻenehana lapaʻau kūikawā kūikawā, ka uhi ʻana a me ka matrix ʻoi aku ka paʻa, kūpono no ke kiʻekiʻe kiʻekiʻe o ke aniani, titanium alloy material precision. wili palaoa.

5135 NC-TIALN uhi i loaʻa iā SI i hui pū ʻia me ka carbide matrix me ka paʻakikī hopena maikaʻi loa, kūpono no nā ʻāpana kila, ke kila kila, ka ʻokiʻoki hohonu, ka hana hānai wikiwiki a me ka hoʻoili ʻana o ka aperture nui.

Palapala noi

Ke noi nui:No ka hana ʻana i ke kila kalapona, ka hao, ke kila kila

ʻOihana o ka noi:

Hoʻohana nui ʻia ka CNC huli a me ka milling tungsten carbide mea hoʻokomo i nā huahana i: ʻoihana hana kaʻa, ʻoihana hana Mold, ʻoihana mokulele, ʻoihana pale, ʻoihana hana kaumaha a me nā kula ʻē aʻe he nui.

hiki iā mākou ke hana i nā ʻano mea ʻoki ʻoki tungsten carbide e like me nā kiʻi kiʻi like ʻole.

hiki iā mākou ke hāʻawi i nā hāʻina kākoʻo holoʻokoʻa no ke kahua mīkini.

Nā Kūlana Huahana

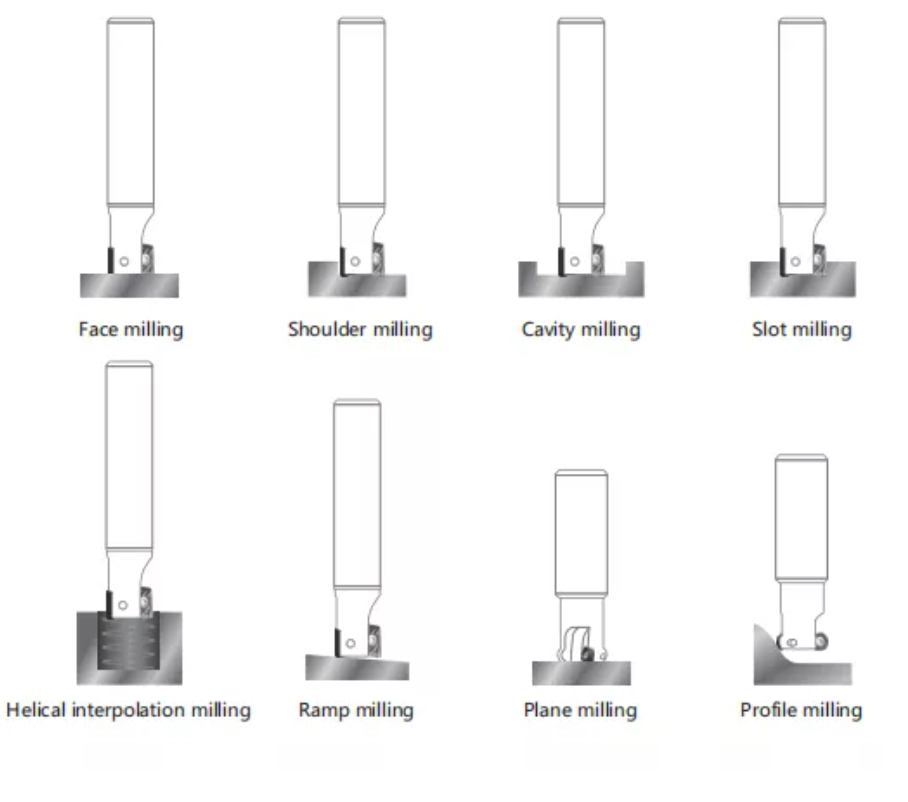

Inā makemake ʻoe i nā mea wili maʻamau a i ʻole nā mea hoʻokomo wili kaumaha no ka wili maka, ka wili poʻohiwi, ka milling slot, ka milling profile, a i ʻole ka milling ramp, a i ʻole ka wili ʻana i nā koi kiʻekiʻe o ka laumania o ka ʻili, hiki i kā mākou ʻenekini ke hoʻololi i kāu hoʻolālā i mea hoʻokomo wili i nā lā wale nō.

Hōʻike uhi

Palapala

Mea Hana Hana

Nā lako QC

Pono

1.ʻO ka hana kūpono, paʻa a hilinaʻi

2.ʻO ke kūlana kiʻekiʻe me ke kumukūʻai hoʻokūkū

3.Hoʻohana nui ʻia i ka ʻoihana o nā mīkini hana metala

4.ʻO nā ʻano like ʻole, hiki ke hana ʻia e like me ke noi a ka mea kūʻai aku